I make custom bicycles by hand, one at a time. My production is limited and my time is valuable to me. I work with clients all over the world who trust me to build them a custom bicycle. Their enjoyment, but most of all, their safety, depends on the quality of my work. I don’t cut corners.

So at some point, an artisan bicycle frame builder needs a lathe for his shop.

Sure, I could go look for a classic lathe on eBay or some other place where one can pick up an older model. Heck, these things are being sold for scrap metal prices these days. I purchased a Kondia vertical mill in Great Britain as well as a Bridgeport in Germany, both off of eBay. I paid more for the shipping to my shop than for the machinery itself.

For the lathe, since I was on new turf, I figured I’d splurge and buy a product with representation in Italy. A company that could help with aftermarket products and optional parts to build up my machinery. After looking around, I came upon Damatomacchine. They supplied Chinese-made machines, but I figured that since they sold them locally, I could count on them for service after the sale.

I took time off work to go to their showroom to view the machines under power and to get to know the people that were helping with my purchase. It was about what I expected. A nice girl met me and introduced me to the technicians who would show me how the machines could handle the titanium samples that I brought with me to test out. After a short test drive, we discussed delivery and pricing, after which I was introduced to the owner. I was left feeling that I was in good hands, so I returned home.

Days later, I ponied up the €5770.00 for the Multitech 1000.51. The top of the line metal lathe with visualized DRO. I also purchased a set of tooling for the machine as well as a “deluxe” quick-change tool holder. I wanted to start out with all the necessary parts to get up and running with my new lathe. I had found multiple versions of this exact machine on Alibaba during my research, with pricing in the neighborhood of €2500.00. Yes, I was paying much more for the same item, but I was convinced that having each machine pass through the Italian company, there were more eyes on the quality aspect as they had built a business model on this idea, employing somewhere around 20 people full time (at least from what I could ascertain during my shop visit.

So far..so good..

My lathe arrived as expected about a month later. Once positioned in my shop, I couldn’t wait to get started playing. I pulled out the tool holder, the deluxe quick-change one I paid extra for. . My contact, the sweet girl who was doing all the coms, told me that the lathe would ship with the standard basic turret. Now I understand why. I spent the next two days trying to get the deluxe turret to sit right on the turret platform. It was not happening.

I contacted Damatomacchine for technical assistance…

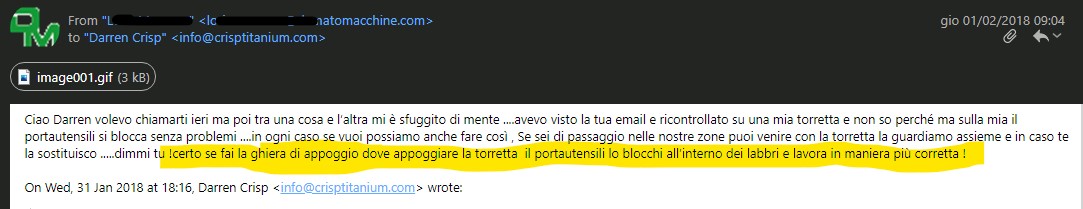

I was told that if I could come by their shop, we could look at the problem together.. I should have taken them up on that offer. Instead, I was offered a reply that contained this phrase:

“certo se fai la ghiera di appoggio dove appoggiare la torretta il portautensili lo blocchi all’interno dei labbri e lavora in maniera più corretta !”

“Of course, if you make the spacer ring for the turret to sit on, you can block the tool holder within the workspace and work in a more correct manner. “

Great start for some new machinery, huh? When the seller says that you’d be working in a more correct fashion by making your own adaptor for the original part, that is a first sign that something is way wrong. It would be like me selling a custom bicycle frame to a client. Then, when the wheels don’t fit, telling them that it would be a superb idea if they could make some adaptors to fit their wheels..no..wait..the wheels that I supply…

Let me get this straight. Even if I wanted to make my own adaptor, I couldn’t, because my turret didn’t fit on the goddam machine. I have to go to my local machine shop, have them use their lathe to make me a part for my new lathe, to make it work. Yes, that’s what I had to do.

Upon closer inspection, I noticed that the lathe did not contain sufficient lubricant as the gear oil level window was showing no oil in the gear housing. Over the next few days, I realized where all the oil had gone…

I opened the inspection door on the side of the lathe. There was no oil plug. After a closer look, I understood why. There was a bolt that was inserted for the front face of the machine, and it had penetrated the oil plug threads, making it impossible to plug the oil port for the gear housing. How this was possible is beyond my wildest dreams. An oversight of this nature is pure neglect not only in the quality control phase of a product, but in the actual development of the product itself. From China, this defective product made it past many “QC” checks on two continents (at least), and was sitting on my shop floor, broken and bleeding out.

The beautiful part of this drama is that I can’t just unscrew the bold and shorten its length or change it out. I have to disassemble the gearbox and gearing of the lathe just to get to this particular bolt.

Yes, Damatomacchine was also in disbelief as to how this could have happened when I wrote them my worrisome letter. Funny, they promote their business as “production and sales of machinery for working with metal and wood”. So, it obviously comes to mind the question: how can the fabricate such a high-end machine that has such a basic design flaw?

After sending more photos and explanations, this is the reply that was returned (05/09/2019):

Buongiorno SIg.Darren,

Mi scuso per il ritardo nella risposta ma ho avuto un problema con alcune email che sono finite nella cartella di spam…..

Allora, per quanto riguarda il foro aperto nel box ingranaggi come ha già identificato e l’ingresso per l’aggiunta di olio, effettivamente lì dovrebbe essere un tappo filettato , ma per qualche strano motivo non c’è!

come ha notato anche Lei hanno messo una vite troppo lunga in corrispondenza di quel foro che arriva alla filettatura del tappo ,c’è qualche filetto che permette di avvitare anche solo di qualche giro un eventuale tappo o va sostituita la vite lunga con una corta in modo con non interferisca?

per la perdita di olio su quella leva di selezione all’interno della testa c’è un albero collegato a una forcella che sposta un ingranaggio , sull’albero è presente una sede per un O-Ring che funge da “guarnizione” probabilmente è da sostituire ,

trova in allegato immagine nel dettaglio quanto detto….

(English Translation)

Hello Mr. Darren,

I apologize for the delay in replying but I had a problem with some emails that ended up in the spam folder …..

So, as for the open hole in the gearbox as you already identified and the inlet for adding oil, there should actually be a threaded plug there, but for some strange reason there isn’t!

as you have also noticed, they have put a screw that is too long in correspondence with that hole that reaches the thread of the cap, there is some thread that allows you to screw a possible cap even a few turns or the long screw must be replaced with a short one in way with does not interfere?

for the loss of oil on that selection lever inside the head there is a shaft connected to a fork that moves a gear, on the shaft there is a seat for an O-Ring which acts as a “gasket”, probably needs to be replaced.

find attached image in detail what has been said ….

Ok, so there is some big-time shit wrong with this machine. This email confirms this fact. “...they have put a screw that is too long in correspondence with that hole “..Who is THEY??? Don’t you mean, “Damatomacchine put this damn screw that is too long?” “…there is a seat for an O-Ring which acts as a “gasket”, probably needs to be replaced.” I need to replace parts on my new, unused machine? WTF? Why? I have to fix a new machine myself?

One day after this email was received from the direct email of the technical assistance, I sent this message:

(1/10/2019)

Ciao Lxxxs,

Grazie per la risposta. Nessun problema con la tempistica, che non ho fretta.

Per quanto riguarda la vite lunga, che sporge nella zona filettatura per il tappo, non so che dire. Mi sembra strano per due motivi: 1. Che è stato realizzato un tornio con una vite così lunga che non permette di inserire un tappo chiusura serbatoio 2. Il tornio è stato consegnato senza tappo.

Entrambi situazioni sono particolarmente incredibile.

Per la perdita d’olio, il problema si è verificato fin da subito e pensavo che era normale con questo tipo di macchina. Invece, indagando con una torcia e una chiave, ho visto che l’olio gocciola lentamente fino al punto interessato (leva di selezione), non permettendomi di riempire il serbatoio in modo regolare (se riempio il serbatoio al livello corretto, tutto va verso il pavimento col tempo, svuotando il serbatoio).

Per la vite, posso risolvere il problema da me. Avrei bisogno di un tappo, però, per chiudere la scatole d’ingranaggio una volta che ho cambiato la vite.

Invece, per l’o-ring, ovviamente questo intervento è più sostanzioso e richiede uno che conosce bene la procedura per risolvere il problema. Non ho esperienza in questo campo. Vorrei sapere come la Vostra azienda si comporta con la garanzia del prodotto.

Grazie per l’assistenza e per i chiarimenti. Rimango a disposizione per ulteriori info se servono.

Distinti saluti,

Darren

(English translation)

Thanks for the reply. No problem with the timing, I’m not in a hurry.

As for the long screw, which protrudes in the threaded area for the cap, I don’t know what to say. It seems strange to me for two reasons: 1. That a lathe has been made with a screw so long that it does not allow the insertion of a tank cap 2. The lathe was delivered without a cap.

Both situations are particularly incredible.

Because of the oil leak, the problem occurred right away and I thought it was normal with this type of machine. Instead, investigating with a flashlight and a wrench, I saw that the oil drips slowly to the affected point (selector lever), not allowing me to fill the tank regularly (if I fill the tank to the correct level, everything goes spills out on the floor over time, emptying the tank).

For the bolt, I can solve the problem myself. I would need a cap, though, to close the gearbox once I have changed the screw.

Instead, for the o-ring, obviously this intervention is more substantial and requires someone who knows the procedure to solve the problem well. I have no experience in this field. I would like to know how your company deals with the product warranty.

Thanks for your assistance and clarification. I remain available if further information is needed.

With best regards,

Darren

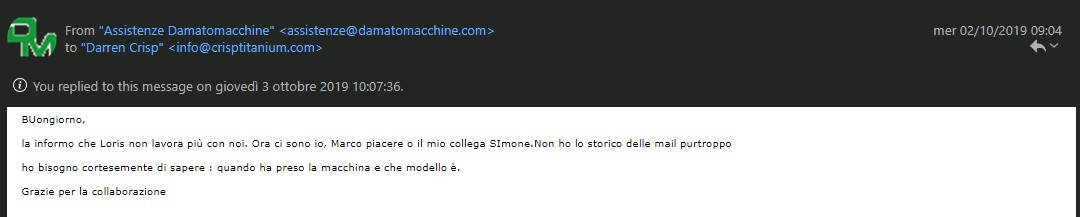

The next day, my technical assistance contact was NO LONGER WORKING WITH DAMATOMACCHINE! Gone.

(02/10/2019)

BUongiorno,

la informo che Lxxxxs non lavora più con noi. Ora ci sono io, Marco piacere o il mio collega SImone. Non ho lo storico delle mail purtroppo

ho bisogno cortesemente di sapere : quando ha preso la macchina e che modello è.

Grazie per la collaborazione

(English translation)

I inform you that Lxxxxs no longer works with us. Now it’s me, Marco pleasure or my colleague SImone. Unfortunately I don’t have the email history

I kindly need to know: when he took the machine and what model it is.

Thanks for collaboration

Ok, so now I start over again, explaining the problem to a new listener. He/they have no dialogue history of my previous messages with Lxxxxs, the technician who was actually trying to help me.

So this is their reply:

04/10/2019

Buongiorno,

allora facciamo questa prova :

– pulisca bene l’olio dal manettino dove perde

– smontando la placchetta si troverò davanti questo (veda allegato)

– sviti le due viti e tiri verso di sè il coperchietto

– dietro il coperchio metta della pasta rossa (veda allegato)

– poi richiuda il tutto

MI faccia poi sapere se avrà nuovamente perdite.

Le spedisco appena mi arriva il tappo che le manca

(English Translation)

Good morning,

then let’s do this test:

– clean the oil well from the handle where it leaks

– disassembling the plate you will find this in front of you (see attachment)

– unscrew the two screws and pull the cover towards you

– behind the lid put some red paste (see attachment)

– then close everything again

Then let me know if you have losses again.

I ship them as soon as I get the cap that is missing

Yes, you read that correctly. Buy this red sealant past and open your machine…apply it after disassembling the front plates…then close everything back..pretend like nothing happened. Pretend like your new €5000 lathe actually works correctly. Pretend that we resolved your problem. Pretend that you didn’t spend a week or more of lost work time disassembling your new machine and instead of producing custom bicycles. Pretend you are fixing our piece of shit lathe with some plumbers putty. Hey, Damatomacchine..go f**k yourselves…

So their solution was limited to sending me an oil plug. Too bad they didn’t consider that I can’t thread the damn thing in, but for only a few threads. Since it is conveniently located in the belt and external gear housing assembly, in just a few uses, it would unscrew due to the machine vibrations and then get thrown into the high-speed gearing, destroying the internal workings of the machine as well as being a safety risk to me or others standing nearby. Yeah, I opted against that solution.

I asked for help. I am not a lathe technician, and my machine had multiple defects that rendered it useless in my shop. I asked for a technician to come take a look and offer some resolution to get this damn machine up and running.

Their reply:

(15/10/2019)

Buongiorno,

ricevuto il tutto. Allora al momento non riusciamo a uscire perché i giri che abbiamo sono completi.

Posso però dirle :

– per la pasta rossa non si deve preouccupare perchè è fatta apposta per ovviare a questi problemi. La pasta dopo essere stata messe tende a indurirsi e fa da muro contro le perdite di olio.

– per il tappo che le ho inviato : se tagliasse via la parte filettata di troppo? Tagliandola a misura poi dovrebbe riuscire a chiudere senza toccare la vite. Anche su questo tappo prima di chiudere, ci metta un poco di pasta rossa

MI faccia sapere

Grazie

(Translated in English)

Good morning,

received everything. So at the moment we can’t get out because all of our technicians are busy.

But I can tell you:

– for red pasta you should not worry because it is made on purpose to overcome these problems. The paste after being put tends to harden and acts as a wall against oil leaks.

– for the cap I sent you: if you cut off the extra threads? Cutting it to size should then be able to close without touching the screw. Also on this cap before closing, put a little red paste in it

Let me know

Thank you

Yep, they’re all booked up. Can’t help me. Sorry. In the meantime, put some plumbers putty on it.

I wrote back..I’ll wait patiently. The lathe is off until I get some professional help. No rush. I want it fixed.

The reply:

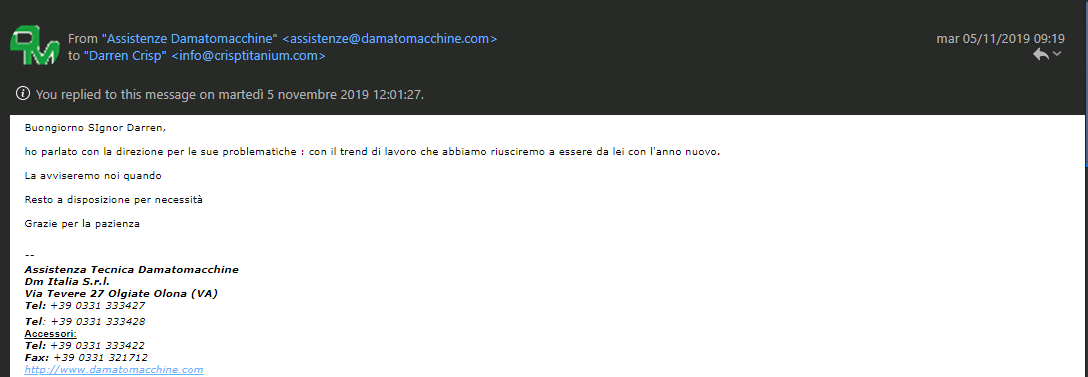

(05/11/2019)

Buongiorno SIgnor Darren,

ho parlato con la direzione per le sue problematiche : con il trend di lavoro che abbiamo riusciremo a essere da lei con l’anno nuovo.

La avviseremo noi quando

Resto a disposizione per necessità

Grazie per la pazienza

(Translated in English)

Hello Sir Darren,

I talked to the management about your problems: with the work trend we have, we will be able to be with you in the new year.

We will notify you when

I remain available for any needs

Thanks for your patience

But wait, there’s more..excuses…

Per la cronaca avendo anche due addetti in malattia ci è tutto più rallentato.

Faremo comunque il possibile per essere da lei nel più breve tempo possibile. Tenga conto comunque il periodo che le ho scritto prima

Grazie

(Translated in English)

For the record, having also two employees on sick leave, everything slowed down.

However, we will do our best to be with you as soon as possible. However, take into account the period I wrote to you earlier

Thank you

Patiently…..8 months later…never heard a word from them..so I wrote back…

(05/07/2020)

Buongiorno,

Sono Darren Crisp, Crisp Cycle (Arezzo). Spero che Voi stiate bene in famiglie e azienda, in questo momento difficile e complicato.

Ci siamo sentiti diversi mesi fa per un intervento sul tornio difettoso. Ora che c’è un minimo di ripresa con il lavoro e trasferte, vorrei chiedervi gentilmente riprendere l’argomento per riparare il mio tornio.

Gradirei programmare un intervento come concordato prima del covid per poter sostituire la guarnizione in quanto il tornio non contiene l’olio di lubrificazione ingranaggi.

Sotto troverai anche dati per la macchina e per le specifiche del problema. Poi, se serve altro, non esitare chiedere.

Attendo notizie e porgo distinti saluti.

Darren

(Translated in English)

I’m Darren Crisp, Crisp Cycle (Arezzo). I hope you and your families are well in this difficult situation.

We spoke several months ago about an intervention on the defective lathe. Now that there is a minimum of recovery with work and travel, I would like to kindly ask you to return to the topic to repair my lathe.

I would like to schedule an intervention as agreed before covid to be able to replace the gasket as the lathe does not contain gear lubrication oil.

Below you will also find data for the machine and the specifics of the problem. Then, if you need anything else, don’t hesitate to ask.

I await news, and send best regards.

Darren

Alas..a reply a month later…

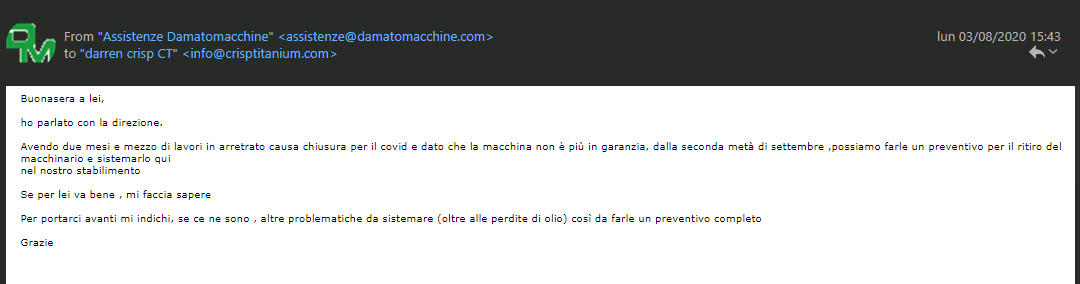

(03/08/2020)

Buonasera a lei,

ho parlato con la direzione.

Avendo due mesi e mezzo di lavori in arretrato causa chiusura per il covid e dato che la macchina non è più in garanzia, dalla seconda metà di settembre ,possiamo farle un preventivo per il ritiro del macchinario e sistemarlo qui nel nostro stabilimento

Se per lei va bene , mi faccia sapere

Per portarci avanti mi indichi, se ce ne sono , altre problematiche da sistemare (oltre alle perdite di olio) così da farle un preventivo completo

Grazie

(Translated in English)

Good evening to you,

I spoke to the management.

Having two and a half months of backlog due to closure for the covid and since the machine is no longer under warranty, from the second half of September, we can make a quote for the collection of the machine and arrange it here

in our factory

If that’s okay with you, let me know

To take us forward, tell me, if there are any, other problems to be fixed (in addition to oil leaks) so as to give you a complete quote

Thank you

Sorry, we’re backlogged 2.5 months because of covid..oh, and your warranty has now expired…if you would like, you can send us the machine and we can fix it here in our factory.

So, like I said at the start of this manuscript. I thought I’d splurge and buy a product with some useful representation in Italy. After all, what is the VAT tax for? Value-added, right? I thought I could find some value in buying locally. I gave them every opportunity to make good on this obvious error and poorly-built machine. The door was open for months, now years…nothing. I thought buying from a reputable company was worth my hard-earned money.

Boy, was I wrong.

Next time I’m buying used machinery on eBay. At least there’s a chance that it will work.